We produce АБЗ (Asphalt plant) with capacity from 15 to 90 t/h.

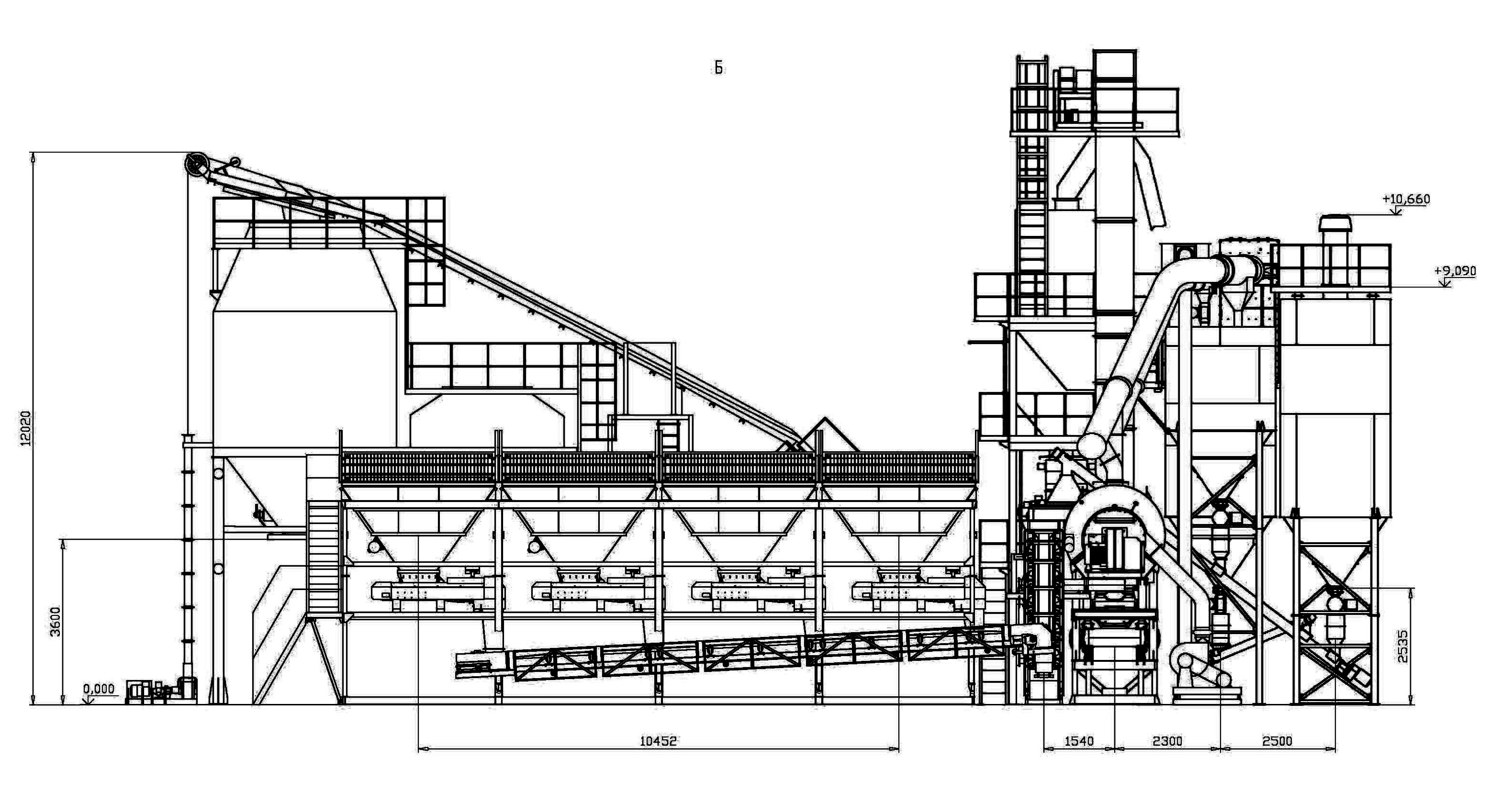

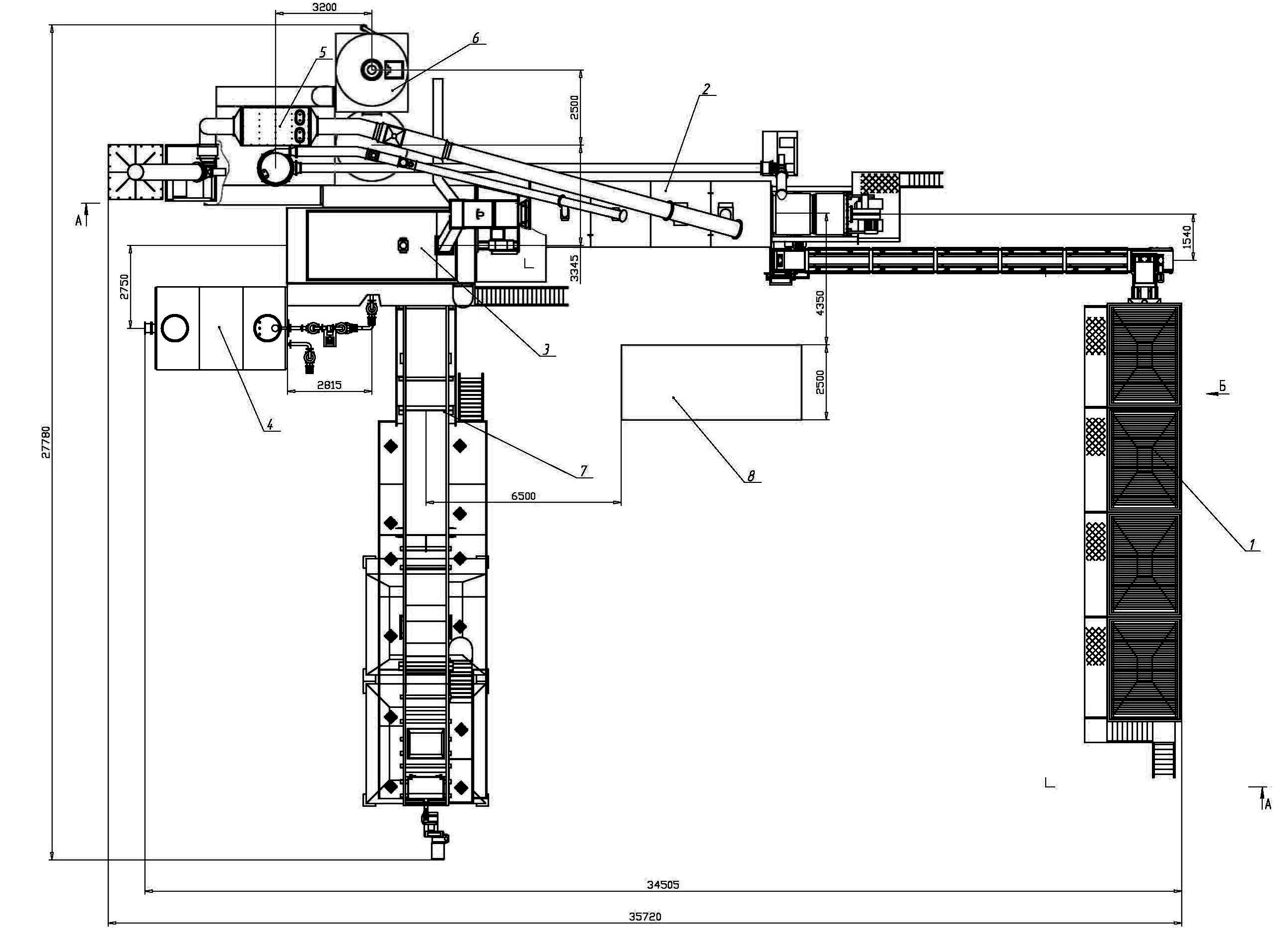

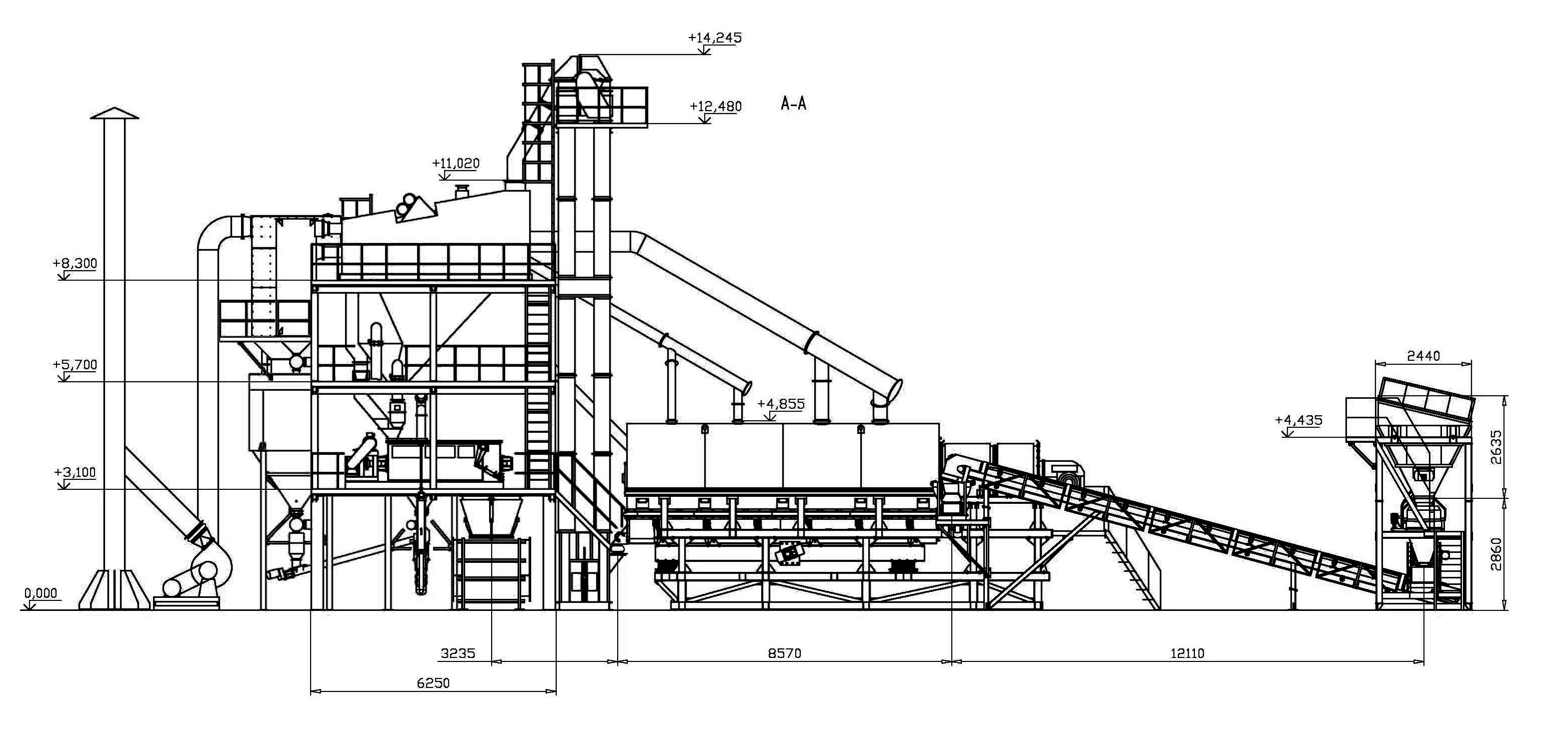

АБЗ-60

The plant consists of the following main aggregates:

1 - Feeder aggregate. It is designed for reception and feeding (dosed) materials (sand, gravel). Composition: receiving hopper (4 pieces), support frame, weight belt feeder (4 pieces), belt conveyor receiving, belt conveyor inclined, vibrating feeder, service platforms, stairs.

2 - Aggregate of drying and heating. It is designed for drying and heating of materials (sand, gravel). Composition: furnace and drying plant, heavy oil burner, working tank of fuel oil, fuel pipe, secondary air pipe, service platform, ladder.

3 - Mixing aggregate. Designed for separation of sand and gravel into fractions (0.16 ÷.1.25mm, 1.25 ÷ 5.0mm, and more than 5.0mm), storage, dosing mixer in fractions of sand and gravel, asphalt concrete components mixing. Composition: elevator, pneumatic switch, vibrating screen, hopper of two parts, continuous operation feeders, mixer, hydraulic station, pipeline bitumen, forehearth of the finished product, supporting structure, service platforms, stairs.

4 - Aggregate of preparation and feeding bitumen. It is designed for storage, dosing, and feeding into the mixer of foamed bitumen. Composition: bitumen plant, continuous operation flow meter, bitumen pipeline.

5 - Gas purification aggregate. It is designed for removing dusty exhaust gases from drying aggregate, cleaning them from dust, separating of large (0.071 ÷ 0.16mm) and small (0.0 ÷ 0.071mm) dust, feeding purified heated air in the drying process or heating aggregates of the asphalt plant . Composition: straight-through cyclones precipitators, bag filters, exhaust fans with guide vanes, sluice gates, chimney (gas flues).

6 - Aggregate of mineral supplements. It is designed for storage, dosing, and feeding of mineral additives in the mixer. Composition: storage (silos) of mineral additives, fine dust hopper, coarse dust hopper, sluice gates, flow meters of continuous operation, screw feeders, service platforms, stairs.

7 - Aggregate of ready mix. It is designed for storage and feeding finished asphalt concrete for shipment in vehicles. Composition: skip hoist, storage bunkers, supporting structure, service platforms, stairs.

8 - Control system. Control of the asphalt plant aggregates automatically, remotely or manually. Composition: operator cabin, remote control, power cabinets, pneumatic control, sensors kit.

The plant can be equipped with aggregates for storage and feeding frezezh, fiber, chemical additives (surfactants, polymer modified asphalt cement ...), and other materials.

Basic specifications of Asphalt and Concrete Mixing Plant АБЗ

| Performance (technical) at 5% moisture fillers, t/h | 60,0 | |

Capacity of reserve components hoppers, m3 |

Hopper of fillers (feeding aggregate) | 4х8,0 |

| Bitumen storage | 40,0 | |

| Storage (silos) of mineral powder | 25,0 | |

| Hopper of dry fillers (fractions 0.16 ÷ 1.25mm) | 5,3 | |

| Hopper of dry fillers (fractions 1.25 ÷ 5.0mm) | 2,2 | |

| Coarse dust bin (fractions 0.071 ÷ 0.16mm) | 12,4 | |

| Bunker of fine dust (fractions 0.071 ÷ 0.16mm) | 11,0 | |

| Hopper of ready mix aggregate | 65,0 | |

| The initial temperature of the sand and gravel, °С |

not less than +5,0 |

|

| Type of fuel |

Liquid, natural gas |

|

| The heating temperature of the starting materials, °С | sand and gravel |

175,0 |

| bitumen | 150,0 | |

| heavy fuel oil | 90,0 | |

| The temperature of the thermal agent into the dryer, °С | 900,0 | |

| The flue gas temperature, °С | in the 1st zone | 75,0÷95,0 |

| in the 2nd zone | 160,0÷180,0 | |

| The oil (gas) for 1 ton of asphalt and concrete mixture, kg/t (m3/t) | when the initial humidity of fillers is 3% | 4,4(5,4) |

| when the initial humidity of fillers is 5% | 5,4(6,64) | |

| when the initial humidity of fillers is 7% | 6,77(8,31) | |

| Measuring hoppers | continuous operation | |

| Dust collecting device | bag filters | |

| The efficiency of gas cleaning aggregate, % | 99,93 | |

| Emission of dust into the atmosphere, mg/m3 | no more than 20,0 | |

| Mixer | type | continuous operation |

| mixing time (adjustable), s | 90,0÷120,0 | |

| Input voltage and frequency V (Hz) | 380 (50) | |

| Installed capacity, kW | 220,0 | |

| Number of personnel (one shift), persons | Operator | 1 |

| Auxiliary worker (a loader driver) |

3 |

|