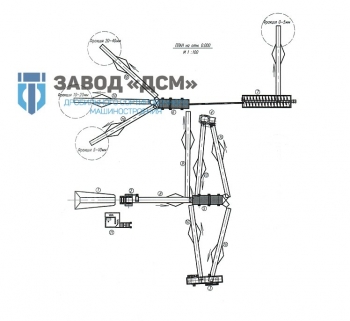

ДСЛ with capacity of 100 m3/h (with the classifier 1КСН-12х80)

This setting is based on ДСУ-90, but with the difference that the finished products (gravel) get washed of clay and impurities. On your screening aggregate ГДСМС-53 (ГИС-53) the washing unit consisting of a system of pipes and nozzles equally spaced above the upper tier screening is installed.

The fraction 0 ÷ 5 after dropping out from the bottom of the screen via the pipeline reaches the spiral classifier 1 КСН-12х80, where the final separation of the fraction 0 ÷ 5 mm (sand) is made.

The installation includes:

| Position | Name | Quantity, pcs. |

|---|---|---|

| 1 | Plate feeder ППДМ-16 (ТК-16) | 1 |

| 2 | Primary crushing aggregate with the jaw crusher ЩДЗМ-6х9 (СМД-110) | 1 |

| 3 | Secondary crushing aggregate with the jaw crusher ЩДЗМ-2,5х9 (СМД-108) – 2 pieces. | 1 |

| 4 | Aggregate of fine crushing with the cone crusher КСДЗМ-900Гр (КСД-900) | 1 |

| 5 | Screening aggregate with screener ГДСМС-52 (ГИС-52) | 1 |

| 6 | Screening aggregate with screener ГДСМС-53 (ГИС-53) | 1 |

| 7 | Spiral classifier 1КСН-12х8 | 1 |

| 8 | The conveyor belt КЛДМ (B=800mm, L=20m) | 1 |

| 9 | The conveyor belt КЛДМ (B=650mm, L=20m) | 1 |

| 10 | The conveyor belt КЛДМ (B=650mm, L=15m) | 8 |

| 11 | Control aggregate У7810.4А | 1 |

- Features

- Video

-

Installation performance, m3/h 90-100 Maximum size of pieces for feeder, mm 500 Tensile strength of crushed material, MPa 300 Hopper capacity of the feeder m3 20 Fractions of the final product, mm 0-5; 5-10; 10-20; 20-40 Total electrical capacity of the line equipment:, kW 350 Size of the site for installation of the line (width x length), m 48х58,4 The height of the ramp, minimum , m 3,4

Download catalog

Order