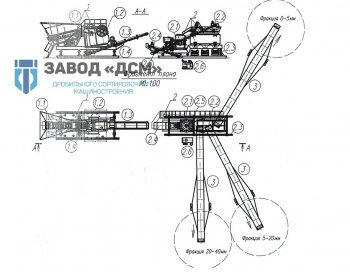

Crushing and screening plant ПДСУ-60

Mobile production line PDSU-60, performance of 60 m3/h

Crushing and screening plant ПДСУ-60 is a mobile high-performance modular system with the possibility of universal use, intended for rubble of three fractions of materials with compressive strength up to 300 MPa. ПДСУ-60 capacity of 60 cubic meters per hour, is designed to fill a niche in the market of medium-performance equipment. The plant consists of primary crushing unit АДЗМ-1, and the secondary unit АСЗМ-2. Both units can be used in-line as well as independently, can be easily moved on the ground inside the building with a bulldozer or a truck, do not require the construction of a foundation that allows consumers to eliminate actually the cost of installation of the equipment.

The structure of ПДСУ-60 include:

| Position | Name | Quantity |

|---|---|---|

| 1 | Primary crushing aggregate АДЗМ-1 | |

| 1.1 | Plate feeder ППДМ-10.49204-10А (ПП-10.49204-10) | 1 |

| 1.2 | Jaw crusher ЩДЗМ-6х9 (СМД-110) | 1 |

| 1.3 | The conveyor belt КЛДМ (b=650mm, L=8m) | 1 |

| 1.4 | Frame of mobile aggregate | 1 |

| 2 | Secondary crushing unit АДЗМ-2 | 1 |

| 2.1 | Cone Crusher КСДЗМ-900Гр (КСД-900) | 1 |

| 2.2 | Screener self-balanced ГДСМ-742А (СМ-742А) | 1 |

| 2.3 | Frame of mobile aggregate | 1 |

| 2.4 | The conveyor belt remote КЛДМ (B=650mm, L=15m) | 1 |

| 2.5 | The conveyor belt returned КЛДМ (B=650mm, L=12m) | 1 |

| 2.6 | Oil-pumping station | 1 |

| 3 | The conveyor belt of finished products КЛДМ (B=650mm, L=15m) | 3 |

Crushing and-screening complexes

Outstanding characteristics of the equipment for crushing are well known. For example, popular in the construction and processing of non-metallic materials jaw crushers effectively crushed granite, cement, limestone, basalt, dolomite, ore, and non-metallic materials with a capacity of 20 to 220 tons per hour; crushing and sorting complex on the site transform primary materials into a finished end product.

The excellent quality of domestic equipment cannot be overestimated: among them, ease of finding the right replacement parts, stable high performance. Skillful use of the advantages that a crushing and sorting complex ДСК, for example, the installation of vibrating screens on the hopper allows obtaining the best quality of products, for example, several product fractions of the material, and so on.

Modern equipment for crushing is required to meet the demands and needs of the market, be cost-effective and ergonomic, providing an effective grinding of mineral raw materials.

The production efficiency of our machines provides a simple and efficient design, which provides protection of the grinding chamber and other parts of the structure from damaging effects. Crushing and sorting complex are adapted for continuous flow production of the final product and efficiently convert solid minerals in the concentrate desired: crushed stone track, building granite, fine-grained concrete, artificial sand, and so on.

Modern ДСО and processing lines can be used for various production requirements: mechanical crushing, sorting with minimal maintenance costs. Crushing and screening plant is focused on the processing of large volumes for better profitability indicators. Each crushing stage operates in optimal performance. The crushing coefficient (or degree) and other measures are observed to achieve it..

At the same time to produce small fraction of the product is reasonable to use the mill equipment.

The price of crushing machines, of course, makes attentive to purchase. Even an uninformed buyer should be aware of the power and the right type of crushing equipment he needs, otherwise the profitability of the use of technology will inevitably decline.

All ДСО, ДСК, МДСК, manufactured by the company, are distinguished by the possibility of active and constantly crush of very different rock, to produce primary processing and recycling of materials. Manufacturing, installation, operation, and maintenance of crushing machinery of LLC "Crushing and Screening Mechanical Engineering Plant" are as simple as possible to ensure that the manufacturer finally had the opportunity to engage in the production, rather than a permanent maintenance and repair of equipment.

- Features

- Video

-

Installation performance, m3/h 60 Maximum size of pieces for feeder, mm 500 Tensile strength of crushed material, MPa 300 Hopper capacity of the feeder m3 12 with ramp; 5 without ramp Fractions of the final product, mm 0-5; 5-20; (20-40) Total electrical capacity of the line equipment:, kW 180 РSize of the site for installation of the line (width x length), m 20х42 The height of the ramp, minimum , m 4,5